Well I just had to make a post of these knives now that they are completed!

It was a bit of a difficult journey, but I was able to get the results I wanted....and hope the clients will be happy with them.

It all started when a father and son found me via an internet search.

They are hunters and came out to the shop with an assortment of trophy horns and others stuff that they had shot. It seems that they have been to Africa on "safari" and had some natural horn and tooth material they wanted some knives made with; using this material as handle fixtures.

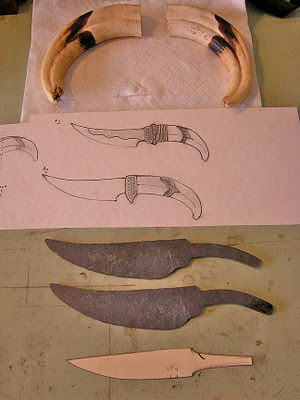

Among the items they had were some really interesting Tusks from a Warthog. These were very cool and as an artist/knifemaker excited me the most. Create a blade-shape and overall style of the knife was next. So I did some conceptual sketches to send them the next day & they left the tusks with me. We decided on the top design & off to work I went creating the blades.

First thing to do was to trim the ends of the tusk down to help create a better alignment for the blades to enter and to get to some thicker material too.

I was amazed that the tusks actually were so amazingly symmetric/a-symmetric when I lined up the openings I had trimmed back!

Next I got down to designing the blade preform. I cut the preforms inspired by the matching aspects of the tusks & intended to make the blades as close to the same as I could. I used Aldo's +.002 3/16" W2 for the blades.....and got down to forging them out.

Then on to some clay coating & Heat Treatment.

I did not get the best hamon lines....live and learn.

Now on to the handle construction. Carving some African Ebony to register into the tusks. These serve as "bolsters" both to support the blade and strengthen the OAL construction of the knives.

I must have gotten excited to get these done because I stopped taking process images from here on out...

So Here are the final Images of the finished knives/ The blades are 5.5"...and an OAL measurement has not been taken, but these are not light-weight knives.

The Turks head knots & wrappings are all epoxy impregnated & the final sharpening of the blades was a blast.... they came-up wickedly RAZOR Sharp.

I hope you enjoyed the journey as much as I have:)