Tuesday, April 30, 2013

Lightweight French Knife

This is one of the thinnest blades I have created to date....and with a very fine distal taper down to a whisper at the tip!

Forged-to-shape out of 1095 and featuring a differential heat treatment creating a blade with a soft supportive spine to the hard cutting edge.

OAL is 14 & 1/8" and the blade is 8.75" tip to heel.

The knife exhibits some very beautiful walnut with structural cocobolo ferrule (creating a mortised construction that is very strong) and cocobolo inlay .

This knife for it's size is very light and quick in the hand; pure-joy for the vegetarian chef or for any one who likes fine chef knives.

This knife will excel in creating wafer-thin cutlets be it meat or veggies and will chiffonade your herbs or greens with ease.

With a bit of blade-weight when held purely at the handle and the balance right at the pinch, just before the handle, this one is made to perform.

I hope you enjoy seeing the images of this fine knife.

-DON:)

Sunday, April 21, 2013

California Custom knives Featured in Edible SLO Magazine ! :)

I could not be more pleased to have been asked to be in Edible SLO Magazine!

What a great opportunity this was and I think they did a great job! A BIG THANKS go out to Karrie Crane and Daniel Kuras for their efforts in representing what I do so well.

Friday, April 19, 2013

Tiber Canyon Ranch April 27-28 2013 from 12noon >5P......

Tomato Fandango and Spring Food Festival

I invite you to come out and have a great time! Below are some more details about this years event and also some images of the knives I will have on display and for sale.

|

|||||||||

|

Tuesday, April 16, 2013

Personal Challenge: Make 4-Chef knives in 3-Days!

The following is from a post I did originally on the USN as I was working my way through the 3-day challenge:

Normally I have anywhere from 30-40 hours in every knife I make...so it's a stretch to say the least.

I did however forge the four blades this AM. lunch now then back to do stock reduction, thermal-cycling & if all goes well I'll heat treat the blades this evening.

Wish me luck!

-DON

Who's idea was this anyhow!

Well I reached my first goal of forging and heat treating four chef knife blades in one day. they are in the oven tempering for the first time right now.

I will feel better once I etch each one to see what the temper-lines look like....the artist in my just can't leave that sh** alone!

For now just a few images of the forged blades, (profile cleaned-up for got to take that pic then radiused the spines & the first sub critical thermal cycle....yes still draw-filing even though I have a grinder!

then radiused the spines & the first sub critical thermal cycle....yes still draw-filing even though I have a grinder!

I'll post more images tomorrow.

Have a great night.

We'll see if I can keep up the flow...I might have to deviate to the hot-springs in the AM just to sooth the neck and shoulders. I have never forged and heat treated even one blade in a day before & today I did the four.

My lady asked if I was on crack!

-DON

Thanks for the interest everybody.

Here is a quick shot of the heat-treated blades. I get concerned at the colors in them due to the atmosphere in my oven....they look darker than I would like, but when I checked them they are just right!

Today:

Clean up the blades & give a quick etch to see what's-up...it looks god to me though so far.

Then doing some post-HT stock-reduction to get these blades really thin & just right.

Choose some wood for the handles, dial-in the tang & fit to each block of wood...believe it or not this may take most of the day.

OK a shot of the blades as they sit now in the studio:

OK Day two and all is going pretty well. things slowed down a bit today but this part is always sort of slow.

Started by doing some post HT stick reduction using a combination of a water-fed lapidary belt sander and my variable-speed angle grinder with a stiff non-flexible back-up pad. I have been doing this for over a year with the hand-held and it works great for me...I look forward to learning how to do this all with the TW90..that day is coming.

OK So here is the list again with some images:

Post HT stock reduction, Dialing-in these thin chef knife blades takes time & patience!>

Next was a quick etch. I would have liked a bit deeper hard-zone, but I can live with it and I'll make any customer a new knife for free if they sharpen past this hard-zone in their lifetime!

AND some of the ABS-Crew rag me on the fact that I do no harden the entire blade on my chef knives... Well I do this for several reasons.

#1, the feel & flex, just can;t be beat with a differential heat treatment.

#2...when etched it just looks cool

#3 you can straighten them later-on! more critical on the larger knives. These actually came out really straight, but I am obsessive about edge geometry and straightness.

.........You might think this is no big deal...sure you have that few moments after the quench,

but these thin blades come down in temp back to magnetic pretty quickly, the shop is all darkened-out & what a pain if you do not get it on a full hardened blade. OK That's my rambling on that.

Next was to choose some wood. I went to one of my stashes in my house in the closet down stairs near my studio &

...from left to right

African Blackwood...I have a ton of that as you can see & really like it.

Kingwood

Desert Ironwood

Cocobolo

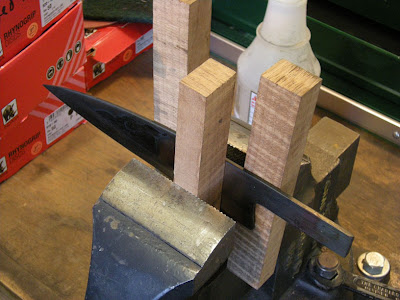

Next it to dial-in the tang.

I could have forged them all the way down but I prefer to do this part more slowly and carefully. This alignment to the notch, called a "Machi" in the Japanese world of chef knives, really creates the attitude and alignment of the handle-to-blade & is critical for chef knives to be right.

In the Japanese world of chef knives they tend to let the Machi stick out quite a bit I prefer to have the support of the machi registered into the wood &

to have the heel-edge of the blade nearer to right-under the front of the handle I think for performance this just rocks.

......but I know there are tons of traditional Japanese culinary techniques where this room is desired and possibly even needed.

...and guess-what?? I used the TW90 to do this part after filing in the notch:)

And the end of day #2:)

Tomorrow will be cleaning up the front of the handle, re-fitting the tang to the pre-fit epoxy

Choosing some inlay contrasting elements to the handle materials & deciding if I will pin these blades or not. IF I pin them each handle will have two inlays, one over a blind pin.

So far so good -DON:)

-DON:)

_______________________

Why did I do it?

Was it about Ego? > very possible

Was it because I get so tired of my knives taking so long to make? > Most Certainly.

Was it because I am a work-a-holic? YES.

What did I learn?

I learned that I truly love making knives and that I mostly love making them slowly.

I learned that with some serious attention, spiritual practice and energy applied, almost anything any of us decide to do, can be achieved.

I learned that it really takes a ton of focus to make a knife no matter what! Chef knives honestly fall into their own category & are sorely underestimated in terms of difficulty to make. They look oh-so-familiar but honestly are not an easy knife to make even though they look like it.

I learned that I am an artist above all else & a bladesmith/knifemaker second...well I already knew this but what the hell, nothing like making 4-chef-knives in 3-days to remind me of this!

I learned that I could work on these knives for three more days doing little things like carving polishing etc...and most likely will. I still have to make the slip sheaths for them and sign them all so in a way they really are not done, but done enough for my little self imposed experiment.

Thanks so to you all for following this whole journey! AND for the kind words and encouragement.

I send you all many Blessings of Health and Goodness!

________________________________________________

Alright, so today started out re-fitting the tangs to the handles. This normally goes pretty smoothly and did so today.

Then drilling the holes for the inlay, choosing inlay contrasting woods that would look cool & creating them.

I decided that these would go a different way than originally planned..... Originally I was NOT going to pin these. Most Japanese Chef knives have no pin. Also I have begun to dislike seeing the pin on stick tang knives & so another inlay was needed...more time.

ALSO, I was not going to etch these blades but the original idea again was to try out a machine-finished blade that would be less $ etc...

....that all went out the window when I realized that it's just not me, not my style not what I like making.

I make fine chef knives & really do not plan on competing with lesser expensive creation...so there

Even though I finished the knives by then end of the 3rd-day...I just could not help but work on them some more. I decided to polish the blades and do some detail carving on them & now I believe they really look amazing!

Not 100% sure what made me do it, but you can check the WIP Thread that I started just a few days ago to read & see more>> http://www.usualsuspect.net/forums/s...-the-challenge

It was an exercise in skill and time, patience or possibly > no-patience,...

....not much time to really think much at all, just kept working to see if it was possible.

I will not be repeating this self-imposed challenge again any time soon!

I hope you all enjoy the images of these finished knives:)

__________________________

Can I make 4-chef Knives in 3-days? I'm going to do my best & find out.Normally I have anywhere from 30-40 hours in every knife I make...so it's a stretch to say the least.

I did however forge the four blades this AM. lunch now then back to do stock reduction, thermal-cycling & if all goes well I'll heat treat the blades this evening.

Wish me luck!

-DON

Who's idea was this anyhow!

Well I reached my first goal of forging and heat treating four chef knife blades in one day. they are in the oven tempering for the first time right now.

I will feel better once I etch each one to see what the temper-lines look like....the artist in my just can't leave that sh** alone!

For now just a few images of the forged blades, (profile cleaned-up for got to take that pic

then radiused the spines & the first sub critical thermal cycle....yes still draw-filing even though I have a grinder!

then radiused the spines & the first sub critical thermal cycle....yes still draw-filing even though I have a grinder!I'll post more images tomorrow.

Have a great night.

We'll see if I can keep up the flow...I might have to deviate to the hot-springs in the AM just to sooth the neck and shoulders. I have never forged and heat treated even one blade in a day before & today I did the four.

My lady asked if I was on crack!

-DON

Thanks for the interest everybody.

Here is a quick shot of the heat-treated blades. I get concerned at the colors in them due to the atmosphere in my oven....they look darker than I would like, but when I checked them they are just right!

Today:

Clean up the blades & give a quick etch to see what's-up...it looks god to me though so far.

Then doing some post-HT stock-reduction to get these blades really thin & just right.

Choose some wood for the handles, dial-in the tang & fit to each block of wood...believe it or not this may take most of the day.

OK a shot of the blades as they sit now in the studio:

OK Day two and all is going pretty well. things slowed down a bit today but this part is always sort of slow.

Started by doing some post HT stick reduction using a combination of a water-fed lapidary belt sander and my variable-speed angle grinder with a stiff non-flexible back-up pad. I have been doing this for over a year with the hand-held and it works great for me...I look forward to learning how to do this all with the TW90..that day is coming.

OK So here is the list again with some images:

Post HT stock reduction, Dialing-in these thin chef knife blades takes time & patience!>

Next was a quick etch. I would have liked a bit deeper hard-zone, but I can live with it and I'll make any customer a new knife for free if they sharpen past this hard-zone in their lifetime!

AND some of the ABS-Crew rag me on the fact that I do no harden the entire blade on my chef knives... Well I do this for several reasons.

#1, the feel & flex, just can;t be beat with a differential heat treatment.

#2...when etched it just looks cool

#3 you can straighten them later-on! more critical on the larger knives. These actually came out really straight, but I am obsessive about edge geometry and straightness.

.........You might think this is no big deal...sure you have that few moments after the quench,

but these thin blades come down in temp back to magnetic pretty quickly, the shop is all darkened-out & what a pain if you do not get it on a full hardened blade. OK That's my rambling on that.

Next was to choose some wood. I went to one of my stashes in my house in the closet down stairs near my studio &

...from left to right

African Blackwood...I have a ton of that as you can see & really like it.

Kingwood

Desert Ironwood

Cocobolo

Next it to dial-in the tang.

I could have forged them all the way down but I prefer to do this part more slowly and carefully. This alignment to the notch, called a "Machi" in the Japanese world of chef knives, really creates the attitude and alignment of the handle-to-blade & is critical for chef knives to be right.

In the Japanese world of chef knives they tend to let the Machi stick out quite a bit I prefer to have the support of the machi registered into the wood &

to have the heel-edge of the blade nearer to right-under the front of the handle I think for performance this just rocks.

......but I know there are tons of traditional Japanese culinary techniques where this room is desired and possibly even needed.

...and guess-what?? I used the TW90 to do this part after filing in the notch:)

And the end of day #2:)

Tomorrow will be cleaning up the front of the handle, re-fitting the tang to the pre-fit epoxy

Choosing some inlay contrasting elements to the handle materials & deciding if I will pin these blades or not. IF I pin them each handle will have two inlays, one over a blind pin.

So far so good

-DON:)

-DON:)_______________________

OK it's the end of the 3rd-day!

And I think I did it.....Why did I do it?

Was it about Ego? > very possible

Was it because I get so tired of my knives taking so long to make? > Most Certainly.

Was it because I am a work-a-holic? YES.

What did I learn?

I learned that I truly love making knives and that I mostly love making them slowly.

I learned that with some serious attention, spiritual practice and energy applied, almost anything any of us decide to do, can be achieved.

I learned that it really takes a ton of focus to make a knife no matter what! Chef knives honestly fall into their own category & are sorely underestimated in terms of difficulty to make. They look oh-so-familiar but honestly are not an easy knife to make even though they look like it.

I learned that I am an artist above all else & a bladesmith/knifemaker second...well I already knew this but what the hell, nothing like making 4-chef-knives in 3-days to remind me of this!

I learned that I could work on these knives for three more days doing little things like carving polishing etc...and most likely will. I still have to make the slip sheaths for them and sign them all so in a way they really are not done, but done enough for my little self imposed experiment.

Thanks so to you all for following this whole journey! AND for the kind words and encouragement.

I send you all many Blessings of Health and Goodness!

________________________________________________

Alright, so today started out re-fitting the tangs to the handles. This normally goes pretty smoothly and did so today.

Then drilling the holes for the inlay, choosing inlay contrasting woods that would look cool & creating them.

I decided that these would go a different way than originally planned..... Originally I was NOT going to pin these. Most Japanese Chef knives have no pin. Also I have begun to dislike seeing the pin on stick tang knives & so another inlay was needed...more time.

ALSO, I was not going to etch these blades but the original idea again was to try out a machine-finished blade that would be less $ etc...

....that all went out the window when I realized that it's just not me, not my style not what I like making.

I make fine chef knives & really do not plan on competing with lesser expensive creation...so there

Even though I finished the knives by then end of the 3rd-day...I just could not help but work on them some more. I decided to polish the blades and do some detail carving on them & now I believe they really look amazing!

Not 100% sure what made me do it, but you can check the WIP Thread that I started just a few days ago to read & see more>> http://www.usualsuspect.net/forums/s...-the-challenge

It was an exercise in skill and time, patience or possibly > no-patience,...

....not much time to really think much at all, just kept working to see if it was possible.

I will not be repeating this self-imposed challenge again any time soon!

I hope you all enjoy the images of these finished knives:)

Thursday, April 11, 2013

Time for a little forge Maintenance

I love my new forge & have been working with it since last year......& now it is time to love it back:)

These furnaces go through an amazing degree of heat and thermal turmoil!

Just check the image below to see what the inside looks like when really going:)

I prefer to start with fixing the cracks in the refractory surfaces with Satanite from K&G Supply.

Then give a light coat of ITC-100. This stuff is nothing short of amazing! It can save from 17-25% on fuel consumption for time run, due to the high degree of reflective boost in the IR-Value. That is no joke. My first experience after re-coating the inside of my old furnace with this special refractory I could hardly look inside as it was so bright!

Anyhow, I look forward to firing it up tomorrow to do some more forging:)

One quick shot of the final and fresh-coat of the ITC-100...at least for now:)

These furnaces go through an amazing degree of heat and thermal turmoil!

Just check the image below to see what the inside looks like when really going:)

I prefer to start with fixing the cracks in the refractory surfaces with Satanite from K&G Supply.

Then give a light coat of ITC-100. This stuff is nothing short of amazing! It can save from 17-25% on fuel consumption for time run, due to the high degree of reflective boost in the IR-Value. That is no joke. My first experience after re-coating the inside of my old furnace with this special refractory I could hardly look inside as it was so bright!

Anyhow, I look forward to firing it up tomorrow to do some more forging:)

One quick shot of the final and fresh-coat of the ITC-100...at least for now:)

Subscribe to:

Comments (Atom)